Post 2 of a series.

——–

After working my way through the first 70 pages of the French text La Menuiserie, I at last arrived at the keenly-anticipated first meaty exercise to be detailed, on Plate 1, entitled, “Pénétration biase de deux parallélépipèdes rectangles”:

The term ’parallelepiped’ is a word which, though seldom encountered by most I would suspect, is a part of the English language. While the term describes a solid comprised of 6 faces which are parallelograms, when you recall that both a square and rectangle are a form of parallelogram (i.e., are 4-sided figures with two pairs of parallel sides), you can see it is a therefore a term with which one can describe a S4S stick of wood. Try throwing that term out to your co-workers on the job site one day and see what sort of response you get - hah! It’s a term you’ll come across in some English 19th century woodworking texts.

The problem is one of a square section vertical post being pierced at an angle by a smaller square-section stick. Note that the smaller stick crosses the post at a given angle, and is not centered to the post, and is itself rotated to a given angle. They are not looking to provide an easily-solved example. The purpose of the Plate 1 study is shown to the right of the sketch above, the développement, which is an unfolded view of the four faces of the post, showing the position and shape of the mortise lines.

I was psyched to dig into this first plate in the text. I cranked the hand wheel, the light’s flickered, a screech of a leather belt and SketchUp came to life. I faithfully drew out the plate in 2D and produced the required unfolded, developed view of the mortises. It seemed straightforward enough to follow the method shown.

Curious to check the result, I then flipped the unfolded view upright, and proceeded to fold the faces inward until I produced a ‘3D’ post. Then I connected the mortise corner lines together within that post. All seemed well as planes were formed within. Then I drew up a second smaller stick of the designed dimension, rotated and tilted it to the correct position and placed it into the through mortise. Jolly nice and all, except it was not even close to a decent fit. Not only was the mortise itself non-square internally, wall to wall, but it was not square dimensionally either.

Huh? I figured I must have blundered somewhere so I drew the entire exercise again, only to reach the identical outcome. Something was haywire. I then decided to do a reverse engineering, making a post without any mortise layout, using the plan and elevation views to place the smaller crossing stick in the correct position and then intersecting the two 3D parts so as to produce the mortise lines on the post. Then I unfolded that post section and laid it flat atop the drawing to compare, thinking that maybe I had simply put one of the mortise corner intersection points in the wrong place or something like that. Here’s the overlay:

As you can see, while the overall mortise outlines are similar in overall appearance, they have only one point in common, at the top, at each side. The lines associating to the white background are in the correct places, while the colored pieces in the background are part of the development done from the original drawing.

The text had to be wrong somehow, as the 3D did not lie, and later that evening, while pacing and bouncing with the baby on my shoulder, I could see what the issue was: something was causing the layout of the mortises on the post to be distorted, and I had an idea as to what the culprit was.

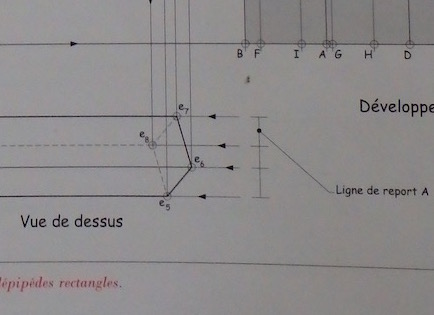

The following morning, when I had a little time, I went back to the sketch and tested out my theory, and then was able to confirm my suspicion. Here’s the problem area of Plate 1:

The square labeled Se1’ through Se4’ is the cross section of the sloped crossing stick. From the four corners, lines are projected plumb down to produce Report Line 'A’.

Report line 'A’ is used to draw the plan view of the stick:

I suspected that the way Report Line 'A’ was established was the kernel of the problem - that report card gets an 'F’ unfortunately.

I placed the 3D stick directly over the plan view to check whether the plan of the stick conformed to the actual outline of the stick - it clearly did not:

A closer look with a couple of width measurements indicated for comparison:

A roughly 4mm difference in plan view width, not to mention the discordant positions of the arris lines, would definitely account for distorted mortises in the development of the mortises on the unfolded post faces.

Just to clarify, the actual crossing piece section conforms perfectly with the elevation view on the drawing, as the traces dropped down to the floor indicate, and is the exact size of the cross section depicted on the elevation view:

Anyhow, shortly afterwards I sorted out the problem with the text’s drawing. The projection from the crossing stick’s cross-section should not drop down plumb, but project square to the stick, like this:

I then swung the lines down to create a similar looking horizontal Report Line 'A’ as the text had shown. These lines could be further extended, if desired, and reflected on a 45˚ line to directly produce the plan view lines for the piece.

With the revision to the report line in place, I re-drew the plan view of the sloped crossing stick, and from there drew out the development one more time:

The 3D stick was then unfolded, and was placed atop the drawing development for a look-see. The mortise outlines on the development and the unfolded stick conformed to one another exactly.

Another view of the post and post assembly with sloped piercing cross piece:

So that was not a promising start to the eagerly-awaited 'meat’ of Volume 3 of La Menuiserie. Planche 1, presumably the most basic exercise, had a serious error.

Well, in truth the method shown was correct save for that one issue (projecting the lines for the 'Report Line 'A’), however that one little mistake threw the development out by more than a little. I’m puzzled how this could have gotten past the editors of the book. Did no one actually make the project? The drawing in the book looks to be produced in CAD, so it seems like they never modeled it in 3D. Or was it so basic a model that a lazy or simple mistake was overlooked? Who knows….

As things have turned out, over the subsequent 7 plates which I have completed, all dealing with the lines of intersection between solids, have all been spot-on, so I think that first plate has an unfortunate error in an otherwise excellent text.

Thanks for dropping by and stay tuned for part III.

via Tumblr http://davidpires578.tumblr.com/post/147519264584

No comments:

Post a Comment